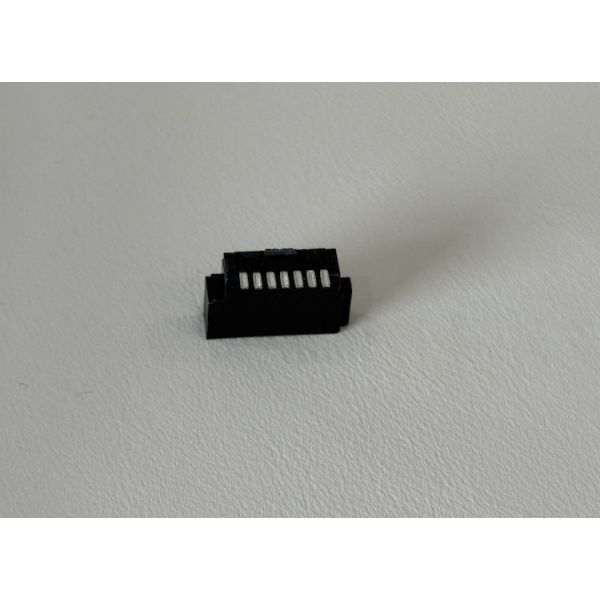

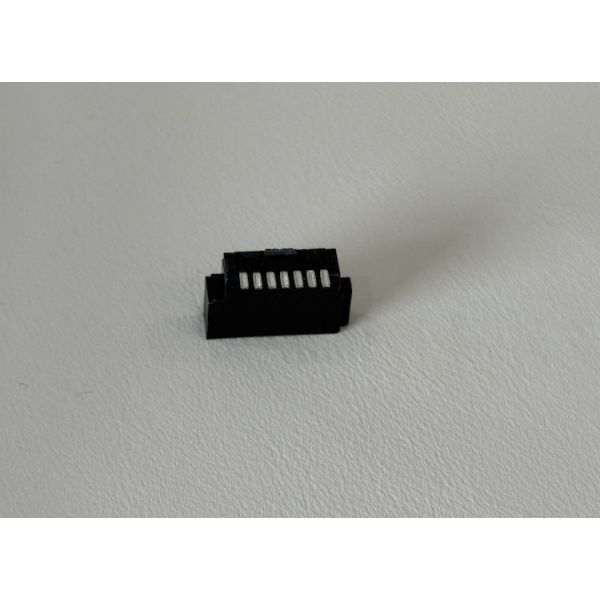

Product Description

This 7 pin SATA female connector is designed for reliable

electrical signal and low-voltage power transmission in compact

cable harnesses. The wire solder termination allows flexible cable

routing and easy integration into custom assemblies for storage,

industrial and embedded systems. Gold plated contacts over nickel provide low contact resistance,

excellent corrosion resistance and stable performance over long

service life.

The high-temperature, flame-retardant thermoplastic housing and

copper-alloy terminals ensure mechanical strength during repeated

mating and handling. The connector supports customization for wire

gauge, cable length, labeling and overmolding, making it suitable

for OEM/ODM projects that require tailored PCB-to-cable

interconnect solutions.

| Connector type | SATA 7-pin female connector, wire solder type |

| Application category | Electrical / electronic signal and low-voltage power connector |

| Positions | 7 contacts |

| Contact pitch | Approx. 1.27 mm SATA contact spacing |

| Termination style | Solder termination for discrete wire or cable |

| Mounting style | For cable harness / wire lead assemblies |

| Contact material | Copper alloy |

| Contact plating | Gold over nickel on contact area, tin on solder area |

| Housing material | High-temperature thermoplastic, UL94V-0 rated |

| Rated voltage | Up to 30 V AC/DC (low-voltage systems) |

| Rated current | Up to 1.5 A per contact (depending on wire size) |

| Insulation resistance | ≥ 1000 MΩ @ 500 V DC (typical) |

| Dielectric withstand | 500 V AC/minute (typical) |

| Operating temperature | −40 °C to +85 °C (wider range customizable) |

| Wire gauge range | AWG 28–24 (other sizes on request) |

| Color | Black housing |

| Custom service | Cable length, wire gauge, plating thickness and labeling OEM/ODM |

Applications

Server and industrial PC SATA storage cable harnesses

Automotive data logging units and on-board storage modules

Embedded controllers and industrial equipment requiring SATA signal

transmission

Custom PCB assemblies in communication, networking and test

equipment

Power and signal breakout cables inside enclosures or rack systems

Precautions

Match the connector with compatible SATA plug connectors to ensure

proper mating and signal integrity.

Select appropriate wire gauge according to system current and

voltage requirements; avoid exceeding the rated current per

contact.

When soldering wires to the terminals, control soldering

temperature and time to prevent damage to the plastic housing.

Provide adequate strain relief (heat-shrink, overmold or clamps) on

the cable to avoid pulling force directly on the solder joints.

Keep contacts and mating surfaces clean and free from dust, flux

residue or oil to maintain low contact resistance.

Do not bend the cable sharply near the connector; maintain the

recommended minimum bend radius to protect conductor and

insulation.

Store and operate the assemblies within the specified temperature

and humidity ranges to ensure long-term reliability.